In this blog post, we dive into the world of Medical Blades, Knives & Keratome, uncovering their varying types, benefits, criteria to choose, how to use, maintenance tips, and the latest technologies and innovations in this field. From surgical applications to ophthalmic and dermatological procedures, these precision tools play a vital role in the medical industry, ensuring accurate and efficient outcomes.

Types of Medical Blades, Knives & Keratome

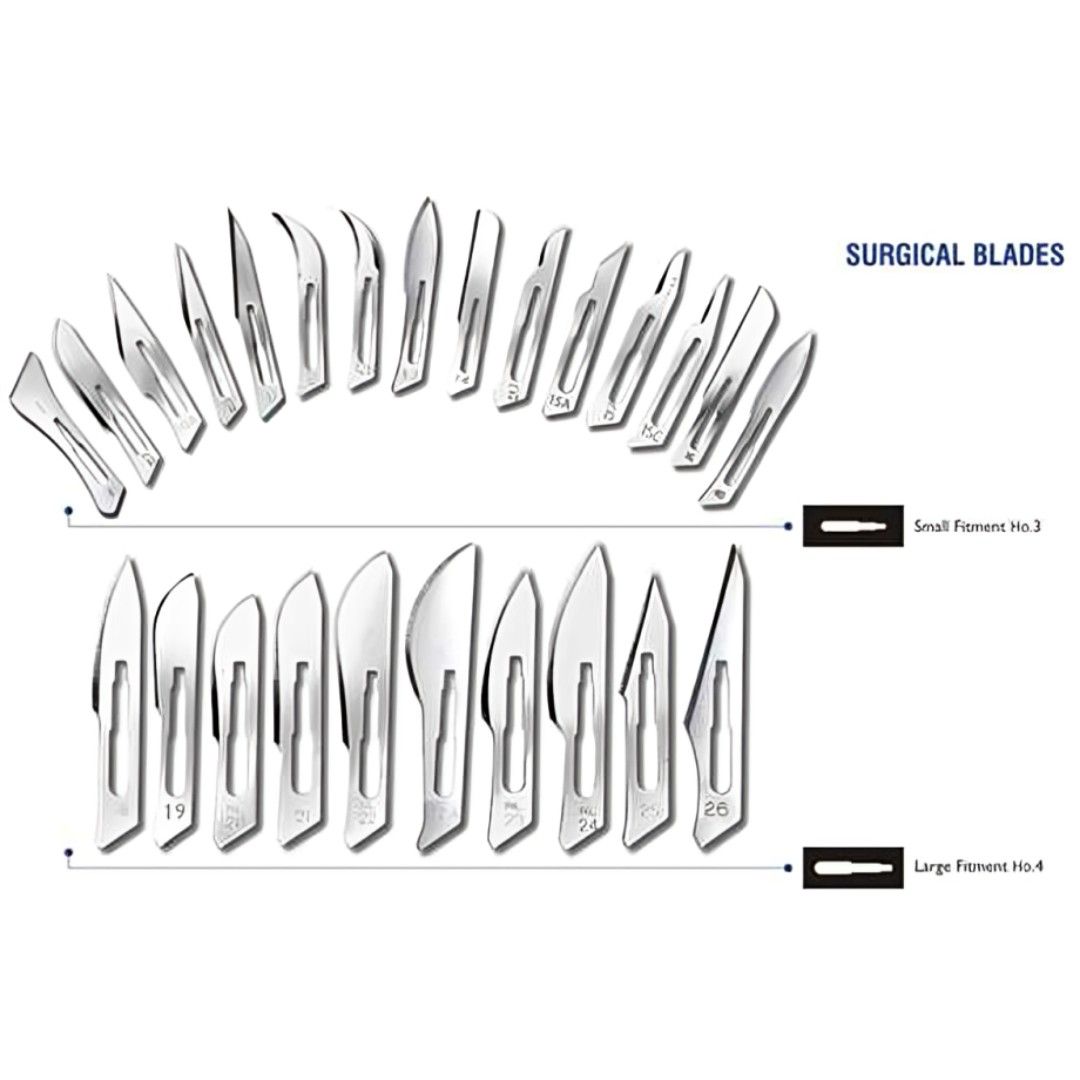

- Surgical Blades: Designed for surgical procedures, these blades offer excellent cutting accuracy and are available in various sizes and shapes to suit different surgical requirements.

- Prep Blades: Specifically used for preparing patients before surgeries and medical procedures, prep blades ensure controlled and precise incisions.

- Ophthalmic Blades: These specialized blades cater to ophthalmic surgeries, offering exceptional precision for delicate procedures on the eye.

- Dermatome Blades: Ideal for dermal grafting and skin grafting procedures, dermatome blades provide controlled thickness and consistency for superior results.

- Blade Remover: This innovative accessory facilitates safe and easy removal of used blades, reducing the risk of accidents and injuries.

- Knives: Specially designed knives serve distinct purposes in the medical field, including tissue dissection, wound debridement, and precise cutting in various procedures.

- Keratomes: These blades find application in ophthalmic surgeries, particularly in corneal transplantations and other corneal procedures.

- Blades: The raw cutting tool that can be attached to various handles and instruments to serve multiple medical purposes.

Benefits of Medical Blades, Knives & Keratome

- Incredible Precision: These tools offer exceptional cutting precision, minimizing tissue damage and promoting faster healing.

- Versatility: With a wide array of blade types available, medical professionals can choose the most suitable one for a specific procedure, ensuring optimal outcomes.

- Efficiency: Razor-sharp edges allow for swift, accurate incisions, reducing procedural time and enhancing overall efficiency.

- Minimally Invasive: Medical blades aid in performing minimally invasive procedures, resulting in reduced scarring and improved patient comfort.

- Consistency: The use of high-quality blades ensures consistent results, enabling medical practitioners to deliver reliable patient care.

Criteria for Choosing Medical Blades, Knives & Keratome

- Blade Material: Look for blades made of high-quality stainless steel, as they offer superior durability and sharpness.

- Size and Shape: Consider the specific requirements of the procedure and choose blades that match those needs to achieve optimal results.

- Sterility: Ensure that the blades are individually packaged and sterilized to maintain strict hygiene standards.

- Compatibility: Check compatibility with the handles and instruments you plan to use, ensuring seamless integration and functionality.

How to Use Medical Blades, Knives & Keratome

- Practice Proper Hand Hygiene: Wash your hands thoroughly and wear sterile gloves for optimal cleanliness.

- Prepare the Patient: Create a sterile field, properly position the patient, and administer anesthesia if required.

- Secure the Blade: Ensure the blade is securely attached to the handle or instrument, double-checking for any looseness.

- Make Controlled Incisions: Maintain a steady hand and use the appropriate technique to achieve accurate incisions, following the procedure guidelines.

- Dispose of Used Blades Safely: Use a blade remover to safely dispose of used blades, minimizing the risk of accidental injuries.

Maintenance of Medical Blades, Knives & Keratome

- Cleaning: After each use, carefully clean the blades using a mild detergent and warm water, ensuring all debris is removed.

- Sterilization: Follow recommended sterilization protocols, either through autoclaving or chemical sterilization methods, to eliminate any residual contaminants.

- Inspection: Regularly inspect blades for any signs of wear, dullness, or damage, and replace if necessary to maintain optimal performance.

- Proper Storage: Store blades in a dry and sterile environment, protecting them from moisture and other potential contaminants.

New Technologies and Innovations

The medical industry is constantly evolving, and so are medical blades, knives, and keratomes. Some of the latest advancements include:

- Nano-coating Technology: Blades with nano-coating offer enhanced sharpness, durability, and resistance to friction, allowing for smoother incisions.

- Laser Precision: Laser technology is being integrated into blade manufacturing processes, ensuring unparalleled accuracy and consistency.

- Ergonomic Handle Design: Innovations in handle design focus on ergonomics, providing surgeons with enhanced control and comfort during procedures.

- Smart Blade Tracking: Some advanced systems incorporate smart technology to track and monitor blade usage, enhancing safety and reducing the risk of using worn-out blades.

Innovative Manufacturing Techniques Used to Create Medical Blades

Innovative manufacturing techniques play a crucial role in creating medical blades, knives, and keratomes with nano-coating, offering enhanced sharpness, durability, and friction resistance. Here are some techniques utilized in this process:

- Physical Vapor Deposition (PVD): PVD is a widely employed technique for depositing thin film coatings onto medical blades and instruments. It involves the use of a high-energy source to vaporize a coating material, which then condenses onto the surface of the blades. This technique enables precise control over coating thickness and composition, resulting in improved wear resistance and cutting performance.

- Chemical Vapor Deposition (CVD): CVD is another method used to apply nano-coatings on medical blades. It involves the introduction of reactive gases into a controlled environment, which react and deposit a thin film on the blade’s surface. CVD offers excellent adhesion and can produce highly uniform and conformal coatings with enhanced hardness and lubricity.

- Laser-Assisted Coating: Laser technology is increasingly utilized in the manufacturing process of medical blades with nano-coating. A high-powered laser beam is employed to ablate or evaporate the coating material, which then deposits onto the blade’s surface. This technique allows for precise control over the coating thickness and can produce highly uniform and consistent coatings with enhanced mechanical properties.

- Magnetron Sputtering: Magnetron sputtering involves the use of a high-frequency plasma discharge to deposit nano-coatings onto the surface of medical blades. It utilizes a target material, typically made of the desired coating material, which is bombarded with ions to dislodge atoms or molecules that subsequently coat the blade’s surface. This technique provides excellent control over coating thickness and allows for the deposition of a wide range of different materials.

- Atomic Layer Deposition (ALD): ALD is a technique that enables precise control over the deposition of the nano-coating layer by sequentially introducing gaseous reactants onto the blade’s surface. It forms a thin film layer one atomic layer at a time, resulting in uniform and conformal coatings with exceptional thickness control and excellent adherence to the substrate.

These innovative manufacturing techniques, combined with careful selection of coating materials, enable the production of medical blades, knives, and keratomes with advanced nano-coatings. These coatings enhance the cutting performance, durability, and overall quality of these instruments, contributing to improved patient outcomes and advancing the field of medical technology.

Spotlight on Ribbel International Limited

Ribbel International Limited, established in 1992 and headquartered in Delhi, India, is a premier manufacturer of medical disposables and consumables. With over 100 employees and an annual turnover exceeding 15 million USD, Ribbel exports products worth between 3 to 10 million USD to regions including Oceania, the Middle-East, CIS nations, South America, North America, Europe, Africa, and Asia. The company holds certifications from TGA, ISO 13485, FDA, and EU CE, ensuring compliance with international quality and safety standards. Ribbel’s product range includes foley balloon catheters, surgical blades, safety scalpels, stitch cutters, gouge blades, curettes, kidney trays, endotracheal tubes, medical blades, urine bags, knives, keratomes, spirometry machines, and surgical trays. The company’s commitment to integrity, continuous improvement, and customer satisfaction has earned it a loyal customer base in 85 countries.

Mini Skin Graft Blade

Among Ribbel’s notable products is the Mini Skin Graft Blade. This surgical blade is designed for high precision, sharpness, and durability, making it ideal for efficient skin grafting procedures. Certified by the FDA, ISO 13485, and EU CE, the Mini Skin Graft Blade is exported to Oceania, the Middle-East, CIS nations, South America, North America, Europe, Africa, and Asia.

Surgical Blades

Ribbel’s Surgical Blades are available in various sizes and shapes to accommodate different surgical procedures. Known for their sharpness, precision, and reliability, these blades are certified by the FDA, ISO 13485, and EU CE.

Post-Mortem Knives

Ribbel also manufactures Post-Mortem Knives, which are high-quality, durable knives designed for precision and efficiency in post-mortem examinations. Certified by the FDA, ISO 13485, and EU CE, these knives are used globally in various regions for forensic and medical purposes.

Blade Remover

The Blade Remover is a crucial tool that facilitates the safe and efficient removal of used surgical blades, minimizing the risk of sharps injuries and promoting sterility in medical settings. This product is particularly in demand in markets such as South Africa, Thailand, Singapore, Kenya, Nigeria, UAE, and the Philippines.

Ribbel International Limited is a trusted and established manufacturer of medical disposables and consumables, with a strong focus on quality, customer satisfaction, and continuous improvement. Their extensive range of products, including mini skin graft blades, skin graft blades, surgical blades, blade removers, and post-mortem knives, meets the highest international standards and is widely used across the globe. Ribbel’s dedication to excellence and its significant global presence make it a reliable partner in the healthcare industry.

Other Top Manufacturers of Medical Blades, Knives & Keratome

There are somany other manufacturers who manufactures medical blades, knives & keratome. Here we are discussing some of the top manufacturers.

- Sterimed Medical Devices Pvt. Ltd.

- Aurolab

- Disposafe Health and Life Care Ltd.

- BLINK MEDICAS IND

- Microtrack Surgicals

- A.S.F. Universal

Conclusion

Medical Blades, Knives & Keratome are indispensable tools in the medical field, enabling precise and efficient procedures across various specialties. With their versatility, exceptional cutting accuracy, and constant advancements in technology, these instruments continue to improve patient outcomes and set higher standards in healthcare. At Medzell, we understand the importance of quality and innovation, offering a wide range of medical blades, knives, and keratome options to meet the evolving needs of medical professionals. Stay ahead with the latest advancements in this field, and pave the way for a brighter and more precise future in healthcare.