Amidst the current global health crisis prioritizing the safety and well-being of both patients and healthcare professionals has emerged as the utmost priority. Disinfection tunnels have emerged as a promising solution, offering an innovative approach to creating cleaner and more hygienic healthcare environments.

This blog aims to equip healthcare facilities with the knowledge and understanding necessary to implement and utilize disinfection tunnels effectively. By exploring the various aspects of this technology, we will delve into the principles, benefits, and best practices for incorporating disinfection tunnels into healthcare settings.

Within this blog you will find all the information about disinfection tunnels and their mechanisms of action. We will delve into the different types of disinfection tunnels available and their specific features, enabling healthcare professionals to make informed decisions about the most suitable options for their facilities.

Whether you are a healthcare administrator, a facility manager or a healthcare professional looking to improve the safety of your practice this handbook will serve as your indispensable companion. By adopting the insights and recommendations presented here, you can take proactive steps toward creating a healthier and safer environment for all. Join us on this informative journey as we pave the way for a new era of advanced sanitization in healthcare facilities.

Understanding Disinfection Tunnels

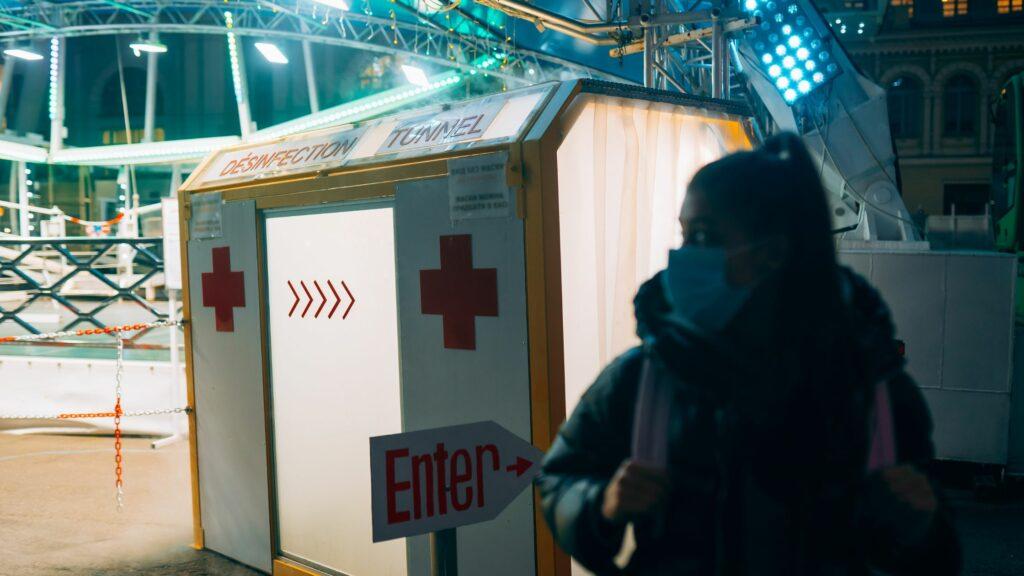

Disinfection tunnels also known as sanitization tunnels or decontamination tunnels are enclosed passageways or chambers designed to sanitize individuals or objects as they pass through. These structures are equipped with various sanitizing mechanisms, such as misting or spraying systems, which distribute disinfectant solutions or other sanitizing agents.

The purpose of disinfection tunnels is to reduce the risk of contamination by eliminating or reducing the presence of harmful pathogens including bacteria viruses and other microorganisms. They are commonly used in healthcare settings, public spaces, industrial facilities and other environments where maintaining high levels of hygiene is crucial.

Disinfection tunnels typically employ different methods of sanitization, such as spraying fine mists of disinfectant solutions, utilizing ultraviolet (UV) light, or incorporating thermal or fogging systems. These methods aim to kill or inactivate pathogens on surfaces or in the air, reducing the potential transmission of diseases. The effectiveness of disinfection tunnels may vary depending on factors such as the type of disinfectant used the design of the tunnel and the adherence to recommended usage guidelines.

Different Types of Disinfection Tunnels

There are several different types of disinfection tunnels available, each employing unique mechanisms to achieve sanitization. Here are some common types:

- Chemical Disinfection Tunnels: These tunnels utilize spray nozzles or misting systems to distribute a disinfectant solution over individuals or objects passing through. The disinfectant can be a liquid or a fine mist. Chemical disinfection tunnels are effective in reducing surface contamination and killing pathogens on exposed areas.

- Ultraviolet (UV) Disinfection Tunnels: UV disinfection tunnels use UV-C light to kill or inactivate microorganisms. As individuals or objects pass through the tunnel, they are exposed to UV-C light, which disrupts the DNA or RNA of pathogens, rendering them unable to replicate. UV disinfection tunnels are commonly used for air and surface disinfection and are effective against a wide range of microorganisms.

- Thermal Disinfection Tunnels: These tunnels employ heat or hot air to achieve sanitization. As individuals or objects pass through, they are exposed to high temperatures, which help eliminate or reduce the presence of pathogens. Thermal disinfection tunnels are often used for disinfecting personal protective equipment (PPE) or other heat-resistant objects.

- Fogging Disinfection Tunnels: Fogging tunnels generate a fine mist or fog of disinfectant solution using high-pressure systems. The fog envelops individuals or objects, effectively reaching and disinfecting hard-to-reach areas. Fogging disinfection tunnels are suitable for large spaces or objects that require thorough sanitization.

- Combined Disinfection Tunnels: Some disinfection tunnels incorporate multiple sanitization methods to enhance effectiveness. For example, a tunnel may combine chemical spraying with UV-C light or thermal treatments to provide comprehensive disinfection.

Benefits of Disinfection Tunnels

Disinfection tunnels offer several benefits in promoting hygiene and safety in various environments. The benefits of disinfection tunnels can be summarized as follows.

- Enhanced Sanitization: Disinfection tunnels provide an additional layer of sanitization, helping to eliminate or reduce the presence of harmful pathogens on individuals or objects passing through. This contributes to creating cleaner and safer environments.

- Reduced Disease Transmission: By effectively targeting and inactivating bacteria, viruses, and other microorganisms, disinfection tunnels can help mitigate the risk of disease transmission. They are particularly valuable in high-traffic areas and environments where infection control is crucial such as healthcare facilities and public spaces.

- Easy and Efficient Operation: Disinfection tunnels are designed for ease of use, typically incorporating automated systems that deliver sanitizing agents consistently. They offer a convenient and time-efficient solution for large numbers of individuals or objects to undergo sanitization.

- Complementary Measure: Disinfection tunnels work alongside other preventive measures, such as hand hygiene and personal protective equipment (PPE), to create a comprehensive approach to hygiene and safety. They complement existing protocols and contribute to a holistic infection prevention strategy.

- Versatile Applications: Disinfection tunnels can be used in various settings, including healthcare facilities, public transportation stations, schools, workplaces, and event venues.

Maximizing Efficiency of Disinfection Tunnels

Advanced disinfection tunnels offer innovative solutions to enhance hygiene and safety in various settings. Here are key strategies to maximize their efficiency.

- Optimal Placement: Position disinfection tunnels strategically in high-traffic areas or at entrances/exits to ensure maximum utilization and coverage. Consider factors like foot traffic flow, accessibility, and convenience for users.

- Suitable Sanitization Methods: Choose the right disinfection tunnel type based on the specific needs of your environment. Chemical spraying, UV-C light, thermal treatment, or fogging—select the method that aligns with your requirements for comprehensive sanitization.

- Quality Disinfectants: Utilize high-quality disinfectants that are effective against pathogens. Follow manufacturer guidelines for proper dilution ratios and safe usage to achieve optimal sanitization outcomes.

- Adequate Training: Provide thorough training to operators responsible for maintaining and operating the disinfection tunnels. They should be well-versed in safety protocols proper handling of disinfectants equipment maintenance and troubleshooting.

- Regular Maintenance: Establish a routine maintenance schedule to ensure that disinfection tunnels are in optimal working condition. Regularly inspect and clean nozzles, filters, UV lamps, or other components as recommended by the manufacturer.

- Monitoring and Validation: Implement a monitoring system to regularly assess the effectiveness of the disinfection process. Conduct periodic validation tests to verify the efficiency of the tunnel in reducing pathogen counts and maintaining desired sanitization levels.

- Integration with Protocols: Integrate disinfection tunnels as part of a comprehensive hygiene protocol, including hand hygiene, mask-wearing, and physical distancing measures. Emphasize that disinfection tunnels are an additional layer of protection, not a substitute for essential preventive practices.

- Communication and Education: Provide clear instructions and informative signage to guide users through the disinfection process. Educate individuals on the purpose and benefits of the tunnel, addressing any concerns or misconceptions.

- Adaptability and Scalability: Assess the scalability of disinfection tunnel installations to accommodate varying needs and demands. Ensure flexibility to adapt protocols based on changing circumstances or emerging guidelines.

Applications of Disinfection Tunnels

Disinfection tunnels offer versatility in their design and application, making them suitable for a wide range of environments and purposes. Here are examples of how these tunnels can be adapted for different applications:

- Healthcare Facilities: Design disinfection tunnels specifically for healthcare settings, considering the unique needs of hospitals, clinics, and laboratories. Incorporate features like antimicrobial materials, UV-C light, and advanced filtration systems to target healthcare-associated pathogens effectively.

- Public Spaces: Install disinfection tunnels in public areas such as airports, train stations, shopping centers, and educational institutions. Ensure user-friendly designs, quick passage through the tunnel, and customizable features to accommodate diverse foot traffic and promote widespread sanitization.

- Industrial Environments: Customize disinfection tunnels for industrial facilities, factories, and warehouses. Consider factors like larger dimensions, robust construction materials, and the ability to sanitize equipment, tools, and work attire effectively.

- Transportation Hubs: Adapt disinfection tunnels for transportation hubs like bus terminals, subway stations, and ports. Incorporate solutions that can sanitize luggage, personal belongings, and surfaces to minimize the risk of cross-contamination during travel.

- Food Processing and Hospitality: Customize disinfection tunnels for the food processing industry and hospitality sector. Implement protocols to sanitize food packaging, kitchen equipment, and uniforms, maintaining stringent hygiene standards.

- Emergency Response: Design portable disinfection tunnels that can be deployed in emergency response situations, disaster zones, or temporary medical facilities. Ensure easy setup, quick decontamination, and compatibility with emergency power sources.

- Customizable Features: Consider customizable features like adjustable spray nozzles, automated sensors, and user-friendly control panels to tailor disinfection tunnels to specific needs. This allows for flexibility in adapting to different applications and environments.

Safety of Disinfection Tunnels

Medical-grade disinfection tunnels are designed to prioritize safety and maintain strict hygiene standards in healthcare environments. Here are key considerations to ensure safety when using these tunnels:

- Compliance with Standards: Select disinfection tunnels that meet or exceed industry standards and regulations for medical-grade devices. Ensure they are manufactured by reputable companies and adhere to quality control measures.

- Effective Pathogen Inactivation: Choose medical-grade disinfection tunnels that employ proven methods for pathogen inactivation, such as UV-C light or approved chemical disinfectants. Verify their efficacy in eliminating a wide range of pathogens, including bacteria and viruses.

- Material Quality: Opt for tunnels constructed from medical-grade materials that are durable, non-toxic, and resistant to corrosion. These materials should be easy to clean and maintain minimizing the risk of contamination.

- Safety Measures: Ensure the presence of safety features, such as motion sensors or automatic shut-off mechanisms, to prevent accidental exposure to disinfectants or UV-C light. Clear instructions and warning signs should be displayed to guide users.

- Proper Training: Provide comprehensive training to healthcare professionals who operate and maintain medical-grade disinfection tunnels. They should understand proper usage protocols, safety procedures, and the handling of disinfectants or other sanitizing agents.

- Regular Maintenance and Validation: Implement routine maintenance schedules to inspect, clean, and replace components as recommended by the manufacturer. Conduct periodic validation tests to ensure the continued effectiveness of the tunnel in reducing pathogen counts.

- Integration with Infection Control: Integrate medical-grade disinfection tunnels as part of a comprehensive infection control program. Emphasize their role as an additional layer of protection and reinforce the importance of other preventive measures like hand hygiene and proper PPE usage.

- Ongoing Monitoring and Research: Stay updated on the latest research and recommendations regarding medical-grade disinfection tunnels. Monitor advancements in technology and emerging best practices to continuously improve safety and efficacy.

Installation & Maintenance of Disinfection Tunnels

Proper installation and maintenance of disinfection tunnels are crucial to ensure their optimal performance and safety. Here are key points to consider:

- Site Assessment: Conduct a thorough site assessment to determine the most suitable location for the disinfection tunnel. Consider factors such as foot traffic flow, accessibility, and proximity to areas requiring sanitization.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s installation instructions and recommended specifications for the disinfection tunnel. Ensure proper electrical connections, plumbing (if applicable), and any structural requirements are met.

- Safety Precautions: Install appropriate safety features, such as motion sensors, emergency shut-off switches, or clear signage to ensure safe operation and prevent accidents.

- Routine Cleaning: Regularly clean the tunnel’s surfaces, including walls, floors, and components, using appropriate cleaning agents and following manufacturer guidelines. Pay particular attention to areas prone to buildup or contamination.

- Disinfectant Refilling: Refill the disinfectant solution or other sanitizing agents as needed, following recommended dilution ratios and safety guidelines. Dispose of any expired or depleted disinfectants properly.

- Component Inspections: Periodically inspect and maintain the tunnel’s components, such as spray nozzles, UV lamps, filtration systems, or fogging devices. Replace or repair any damaged or malfunctioning parts promptly.

- Calibration and Validation: Calibrate sensors and monitoring systems regularly to ensure accurate readings. Perform validation tests to assess the effectiveness of the disinfection process and verify compliance with desired sanitization levels.

- Operator Training: Train designated personnel on proper maintenance procedures, including safety protocols, cleaning techniques, and component handling. Ensure they are knowledgeable about troubleshooting common issues.

- Ongoing Monitoring: Continuously monitor the performance of the disinfection tunnel, assessing its effectiveness in reducing pathogen counts and maintaining desired sanitization levels. Stay updated on emerging research or guidelines related to disinfection practices.

Disinfection Tunnels From Leading Indian Manufacturers

Noviba

Noviba, a state-of-the-art Disinfection Tunnel, is proudly manufactured and globally supplied by Bird Meditech in India. This innovative device is designed to prioritize the safety and well-being of individuals by providing a comprehensive full-body disinfection experience. With its exceptional features and superior construction, Noviba stands as a reliable and efficient solution in combating the spread of harmful bacteria and viruses.

Noviba is meticulously crafted using high-quality SS 304 material, ensuring durability, longevity, and compatibility with healthcare standards. The robust construction of the body guarantees a sturdy and reliable disinfection chamber that can withstand frequent usage without compromising on its performance.

The side walls of Noviba are made of ACP (Aluminium Composite Panels), known for their exceptional strength and resistance to external elements. The windows are crafted from transparent acrylic sheets, providing a clear view of the disinfection process while maintaining a safe and secure environment inside. The floor is constructed with aluminium sheets, offering stability and easy maintenance.

Noviba takes efficiency to the next level by ensuring complete full-body disinfection within just 30 seconds. Its advanced technology and design allow for quick yet thorough sanitization, enabling a seamless and time-effective experience for individuals passing through the tunnel.

The primary objective of Noviba is to combat harmful bacteria and viruses effectively. By leveraging its cutting-edge disinfection mechanisms, Noviba successfully destroys these microorganisms, mitigating the risk of infection and transmission. This feature is particularly crucial in high-risk areas such as healthcare facilities, transportation hubs, commercial spaces, and public venues.

Noviba is equipped with a sophisticated 6 nozzle spray system, ensuring comprehensive coverage and optimal disinfectant distribution. This system guarantees that individuals passing through the tunnel receive a uniform and efficient disinfection process, leaving no room for potential contamination.

To meet varying requirements, Noviba is available with tank capacities of 100, 150, 200, or 250 litres. This versatility allows for customization based on specific needs and usage scenarios, catering to both smaller and larger scale applications.

Noviba, the Disinfection Tunnel by Bird Meditech, is a testament to the commitment to safety and well-being. Its non-toxic, eco-friendly, and easy-to-install design makes it an ideal choice for diverse environments. From healthcare facilities to public spaces, Noviba stands as a reliable and efficient solution in creating safer surroundings. Trust in Noviba to provide advanced full-body disinfection, helping to safeguard individuals from the threat of harmful pathogens.

Introducing Medzell: A cutting-edge B2B platform revolutionizing Indian medical devices access in emerging markets.

Explore a wide array of top-notch Disinfection Tunnels from reputable manufacturers, keeping you up-to-date with the latest advancements. Experience seamless procurement for Disinfection Tunnels and more medical devices as Medzell connects healthcare providers, distributors, and consumers. With its user-friendly interface, vast product catalog, and transparent pricing, Medzell simplifies the process of sourcing Disinfection Tunnels, making it easier for individuals to find the perfect device for their treatment.

Conclusion: Building a Safer Future with Disinfection Tunnels

In this blog, we have explored the world of disinfection tunnels, unveiling their diverse types, benefits, installation processes, and maintenance tips. By embracing the power of disinfection tunnels, healthcare facilities can create safer environments, protect patients and staff, and ensure a brighter, healthier future for all.