As the world becomes more health-conscious, medical facilities should make sure that their cleaning processes meet the required standards. One essential tool in the fight against infections is the Washer-Disinfector. These machines are designed to clean and disinfect medical equipment and surgical instruments.

In this blog, we will explore the benefits of using a Washer-Disinfector and provide practical tips on choosing and maintaining the perfect machine for your medical facility. We will cover topics such as Washer-Disinfector capacity, dimensions, cycle time, safety features, maintenance, and temperature. We will also compare Washer-Disinfector and autoclave machines and explain how to validate the performance of a Washer-Disinfector.

But first, let us introduce you to Medzell, a futuristic B2B platform for promoting Indian medical devices in emerging markets. Medzell offers a wide range of medical equipment, including Washer-Disinfectors, to ensure that medical facilities can provide the best possible care to their patients. Now, let us dive into the world of Washer-Disinfectors and learn how they can help improve infection control in medical facilities.

Washer-Disinfector and its Working

A Washer-Disinfector is designed to clean and disinfect medical equipment and surgical instruments. The process involves spraying hot water and detergent onto the items to remove any dirt or debris. The high-temperature rinse kills any remaining bacteria or viruses. The Washer-Disinfector is a closed system that prevents the spread of contaminated water or air.

Understanding Washer-Disinfector Capacity

Washer-Disinfector capacity is an essential factor to consider when choosing a machine. It determines the number of items that can be disinfected at once. If your medical facility has a high volume of medical equipment or surgical instruments, you will need a machine with a higher capacity. The capacity of the machine should not compromise the quality of its cleaning process.

The Importance of Washer-Disinfector Dimensions

Washer-Disinfector dimensions are another critical factor to consider when choosing a machine. The dimensions determine where the machine can be installed and how it will fit into the available space. Choose a machine that will fit into the available space and allow easy access.

The dimensions of a Washer-Disinfector are another important factor to consider when choosing the right machine for your medical facility. It is essential to select a machine with the appropriate dimensions to ensure that all instruments can be properly accommodated and cleaned effectively.

It is also important to consider the space available in your medical facility for the installation of the Washer-Disinfector. The location should be easily accessible for staff to load and unload instruments.

Washer-Disinfector Cycle Time and its Impact on Efficiency

Washer-Disinfector cycle time is the length of time it takes to clean and disinfect items. It is essential to choose a machine with a cycle time that is efficient but does not compromise the quality of the cleaning process.

The cycle time of a Washer-Disinfector is another important factor to consider when selecting the right machine for your medical facility. The cycle time can vary depending on the type of machine and the type of instrument being cleaned.

It is important to select a Washer-Disinfector with a cycle time that is appropriate for the volume and type of instruments being cleaned. A machine with a shorter cycle time can improve efficiency and productivity, but it may not provide the necessary level of cleaning and disinfection for certain instruments. On the other hand, a machine with a longer cycle time may provide a more thorough cleaning and disinfection but has reduced efficiency and productivity.

Importance of Washer-Disinfector temperature

- The temperature of a Washer-Disinfector is an important factor to consider when it comes to effective cleaning and disinfection. The right temperature ensures that the Washer-Disinfector is able to effectively clean and disinfect medical instruments and equipment, reducing the risk of infections.

- The ideal temperature for a Washer-Disinfector will depend on the type of medical instruments and equipment being cleaned. Generally, a temperature range between 55-65°C is recommended for a Washer-Disinfector, as it is effective in removing dirt and microbes.

- Lower temperatures may lead to ineffective cleaning of the instruments and equipment. Higher temperatures can cause damage to the equipment.

- Regular monitoring of the Washer-Disinfector temperature is important to ensure that it is functioning properly and effectively cleaning and disinfecting medical instruments and equipment.

How a Washer-Disinfector Improves Infection Control

A Washer-Disinfector is a crucial piece of equipment in the battle against infection control. It ensures that medical instruments are effectively cleaned and disinfected, reducing the risk of infection transmission.

Using a Washer-Disinfector in medical facilities can ensure that instruments are properly cleaned and disinfected. Additionally, Washer-Disinfectors are designed to provide consistent cleaning and disinfecting results, which helps to maintain the overall cleanliness of the medical facility.

To sum up, the Washer-Disinfector is a crucial component in maintaining infection control in medical settings.

Ensuring Safety with a Washer-Disinfector

Safety is a top priority in any medical facility, and a Washer-Disinfector is designed with safety features to prevent infection transmission. The machine is a closed system that prevents the spread of contaminated water or air. It also has safety locks to prevent the machine from being opened during the cleaning process.

Safety is a top priority in medical facilities, and a Washer-Disinfector can play a critical role in reducing the risk of infection transmission. Washer-Disinfectors are designed with safety features to ensure that instruments are properly cleaned and disinfected and that staff are protected from exposure to harmful microorganisms.

Some features include automatic locking systems, temperature and pressure sensors, and alarms.

Validating the Performance of a Washer-Disinfector

To ensure that a washer-disinfector is operating at optimal levels and effectively reducing the risk of infection transmission, it is important to regularly validate its performance.

Validation typically involves using test soil to simulate real-world conditions and measuring the effectiveness of the cleaning and disinfection process. This testing should be performed by a qualified professional who has experience with washer disinfectors and understands the necessary standards and regulations.

Using a Washer-Disinfector for Surgical Instruments

Washer-disinfectors are particularly useful for cleaning and disinfecting surgical instruments, which must be thoroughly cleaned and sterilized to prevent infection transmission. Surgical instruments can be difficult to clean by hand, as they often have complex shapes and crevices that can harbor bacteria and other microorganisms.

Washer-disinfectors are designed to effectively clean and disinfect surgical instruments, even those with complex shapes and crevices.

Surgical instruments require a high level of cleaning and disinfection. Washer-Disinfectors are ideal for cleaning and disinfecting surgical instruments because they won’t damage delicate instruments.

It’s important to follow the manufacturer’s guidelines and use the correct temperature, and detergent. Ensure that the instruments are properly loaded to allow for thorough cleaning and disinfection.

Washer-Disinfector: Benefits

- Washer-Disinfectors offer a range of benefits in medical facilities. Firstly, they provide an efficient and effective way to clean and disinfect medical instruments, reducing the risk of infection transmission between patients.

- Washer-Disinfectors are also easy to use and require minimal training, making them a practical choice for busy medical facilities. They can accommodate a wide range of instruments and equipment, from small tools to larger items.

- Using a Washer-Disinfector can also save time and resources in a medical facility, as they can clean and disinfect instruments in a single cycle, without the need for additional manual cleaning. This can lead to increased efficiency and productivity in the facility. Overall, Washer-Disinfectors provide a valuable solution for improving infection control and efficiency in medical settings.

Tips for Maintaining a Washer-Disinfector

To ensure the longevity of your Washer-Disinfector, it is essential to follow proper maintenance procedures.

Proper maintenance is essential to ensure the longevity and effectiveness of a Washer-Disinfector. Regular maintenance can also help to prevent malfunctions and reduce the risk of infection transmission.

Some tips for maintaining a Washer-Disinfector include.

- Regularly cleaning the machine to remove any buildup of dirt or debris

- Inspecting the machine for signs of wear and tear and replacing any damaged parts

- Calibrating the machine to ensure that it is operating correctly

- Regularly checking and replacing the detergent and disinfectant used in the machine

- Conducting regular performance tests to ensure that the machine is operating at peak efficiency

- Regularly inspect and clean the washer-disinfectors filters and spray arms.

- Use only approved detergents and disinfectants.

- Regularly test the performance of the washer-disinfector to ensure it is operating at optimal levels.

- Train staff on proper usage and maintenance procedures.

Washer-Disinfectors from Leading Indian Manufacturers

Instrument Washer Cum Disinfector

The Instrument Washer Cum Disinfector represents cutting-edge medical technology from Cistron Systems Private Limited, a leading manufacturer in India. This cutting-edge device is designed to automatically clean and disinfect instruments, ensuring that they are free from harmful bacteria and viruses.

The Instrument Washer Cum Disinfector represents cutting-edge medical technology from Cistron Systems Private Limited, a leading manufacturer in India. This cutting-edge device is designed to automatically clean and disinfect instruments, ensuring that they are free from harmful bacteria and viruses.

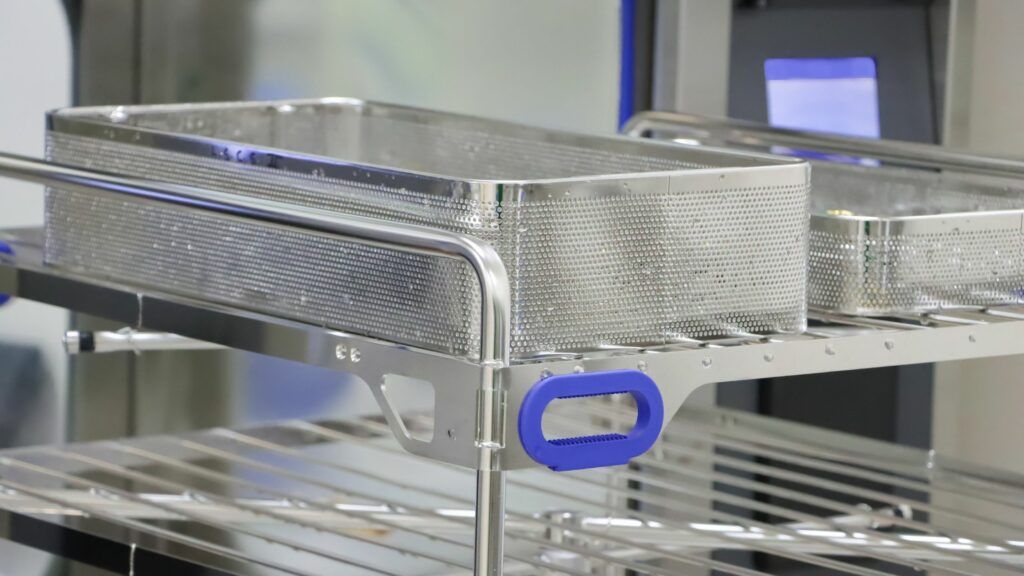

The Instrument Washer Cum Disinfector is made of high-quality stainless steel, both inside and out, making it a durable and long-lasting option for medical facilities. Its strong water pump allows for efficient cleaning and disinfecting, making the process faster and more effective.

A special heating element is provided to boil water up to 80°C, which ensures that the instruments are thoroughly cleaned and disinfected. Additionally, the Instrument Washer Cum Disinfector can also partially dry the instruments, reducing the risk of contamination and improving efficiency.

This medical device comes with six readily replaceable stainless steel trays, providing ample space to clean and disinfect multiple instruments at once. The trays can be easily removed and replaced, ensuring that the Instrument Washer Cum Disinfector can continue to provide optimal cleaning and disinfection results.

In conclusion, the Instrument Washer Cum Disinfector manufactured by Cistron Systems Private Limited is a cutting-edge medical device that provides automatic cleaning and disinfecting of medical instruments. Its sturdy stainless steel construction, strong water pump, and heating element make it a highly effective option for infection control in medical facilities. With six replaceable stainless steel trays, this device provides ample space for cleaning and disinfecting multiple instruments at once, making it a must-have for any medical facility.

Medzell: The Cutting-Edge B2B Platform for Indian Medical Devices

Medzell is a cutting-edge B2B platform that has revolutionized the medical device industry in India. It provides a convenient and efficient way for manufacturers like Cistron Systems Private Limited to promote their products, including Instrument Washer Cum Disinfectors, in emerging markets. Medzell’s platform offers an intuitive interface for buyers to search, compare, and purchase medical devices. With a global reach, it helps Indian medical device manufacturers to expand their business beyond national borders and connect with international buyers. Medzell also provides valuable marketing and branding services to its partner manufacturers, allowing them to showcase their products to a wider audience. Overall, Medzell has emerged as a futuristic platform that is transforming the way Indian medical devices are being promoted and sold in emerging markets.

Conclusion

In conclusion, the Washer-Disinfector stands as a cornerstone of modern healthcare, ensuring the meticulous cleanliness and safety of medical instruments. Its sophisticated technology, exemplified by manufacturers like Cistron Systems Private Limited, underscores the commitment to patient well-being and infection control. By automating the process of cleaning and disinfection, these devices enhance operational efficiency and minimize the risk of cross-contamination. Regular maintenance, adherence to guidelines, and ongoing training are pivotal in maximizing their effectiveness. As we navigate the ever-evolving landscape of healthcare, the Washer-Disinfector remains an indispensable ally, safeguarding both patients and healthcare professionals alike.